The DREMA 2025 trade fair, one of the leading events in the

woodworking and furniture manufacturing industry in Central and

Eastern Europe, has just announced its highly anticipated Gold

Medal winners. DREMA will take place from September 09-12, 2025.

These products represent the cutting edge of woodworking

technology, offering solutions that promise to transform the

future of the industry.

The Gold Medal awards, which highlight the most innovative,

functional, and sustainable products, were presented to

technologies that align with the evolving needs of the

woodworking sector. From automated CNC machining to cutting-edge

edge banders and heat recovery systems, the awarded products are

set to lead the way in productivity, precision, and eco-friendly

solutions for the industry.

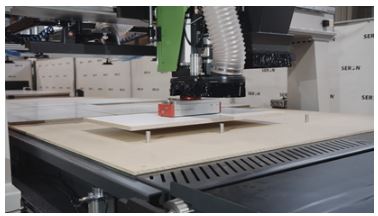

ProNest Automated Machining Centre – SERON Sp. z o.o. Sp. k.

The ProNest Automated Machining and Labelling Centre by SERON is

a game-changer in the furniture manufacturing industry,

particularly for case and upholstered furniture manufacturers.

This advanced device offers cutting, vertical and horizontal

drilling capabilities, making it versatile for working with

wood-based panels and various materials. Equipped with a board

feeding and receiving system, it ensures efficient, error-free

machining, reducing production time and costs while maintaining

the highest quality. The ProNest system is not just limited to

furniture; it can be adapted for other industrial sectors,

making it a highly flexible solution for a wide range of

applications.

AUTONUT CNC 400 M6 – BizeA Sp. z o.o.

BizeA’s AUTONUT CNC 400 M6 is revolutionizing the furniture

production process with its fully automated system for inserting

T-nuts. This innovation eliminates the need for manual labor,

streamlining the insertion process, and reducing errors. The CNC

line automatically picks up the board, identifies the correct

holes, and inserts the nuts with incredible precision. This

automated solution improves efficiency, reduces labor costs, and

minimizes production errors, setting a new standard in assembly

automation. It can operate autonomously or be integrated with a

CNC production line, providing manufacturers with enhanced

flexibility.

1325/10 3D Printer – POLSKA GRUPA CNC Damian Laskowski

For those in the woodworking and prototyping industries, the

1325/10 3D Printer by POLSKA GRUPA CNC offers an excellent

solution for producing precise models using additive

manufacturing technology. Capable of working in three axes

(XYZ), this printer supports a variety of materials such as PLA,

ABS, PET-G, and rubber. The 1325/10’s robust construction, air

cooling system, and interchangeable nozzles make it suitable for

both industrial use and educational projects. With a high print

capacity of 8 kg/h, this printer is an essential tool for rapid

prototyping and small-batch production, offering manufacturers

greater flexibility and speed in product development.

EKOMAT HRTPO – INTERMET KOTŁY GRZEWCZE Sp. z o.o. S.K.A.

In an effort to promote sustainability in the woodworking

industry, EKOMAT HRTPO by INTERMET KOTŁY GRZEWCZE is designed to

efficiently process wood waste through thermal treatment. This

system offers high energy efficiency, reducing heat demand by up

to 25% and lowering electricity consumption. Equipped with a

flat movable grate and a hydraulic drive, the EKOMAT system

ensures optimal combustion of wood waste while meeting the EU’s

stringent environmental regulations. It’s an excellent solution

for companies looking to reduce their carbon footprint and

manage their wood waste more effectively while generating energy

for their operations.

Tempora F1000 Straight Edge Bander – FELDER KG, FELDER GROUP

POLSKA Sp. z o.o.

FELDER’s Tempora F1000 Straight Edge Bander is a

high-performance machine that redefines standards in edge

banding for the woodworking sector. The Format4 series includes

three models—performance, professional, and classic—which can be

tailored to specific production requirements. This edge bander

combines precision, durability, and superior performance,

delivering flawless edge banding for wood and wood-based panels.

Its advanced features make it a top choice for manufacturers who

require consistent, high-quality edge banding, especially in

complex production environments.

Ita Tools Circular Saw – ITA Tools

The Ita Tools Circular Saw sets new standards in the woodworking

industry by incorporating the latest technological advancements.

With its precision tooth geometry and optimised carbide grades

from CERATIZIT, this saw is designed for long life and reduced

power consumption. The saw’s construction allows for

high-quality machining while maintaining excellent durability.

It also features noise-reducing cuts and H7 tolerance mounting

holes for easy installation. ITA Tools’ circular saws are

perfect for demanding customers who require efficiency, quality,

and precision in their cutting operations.

SALVACUT 3000 Optimising Cross-Cut Saw – SALVAMAC Sp. z o.o.

SALVACUT 3000 by SALVAMAC is an innovative cross-cut saw

that features optimisation technology designed for automatic

cutting and defect elimination in solid wood. The SALVA-OPTIM

system uses a touch interface for ultra-fast data processing,

and its dual feed drive ensures high precision and efficiency.

This high-speed machine is designed for integration with digital

production flows, allowing woodworking companies to achieve top

productivity while maintaining high-quality standards in wood

cutting. The SALVACUT 3000 is ideal for manufacturers looking to

automate and streamline their cutting processes.

Mühlböck 1306 PRO Heat Recovery System – MÜHLBOECK

HOLZTROCKNUNGSANLAGEN GmbH

In a move toward energy efficiency and sustainability,

Mühlböck’s 1306 PRO Heat Recovery System offers wood dryers an

innovative way to reduce energy consumption. By recovering heat

from the drying process, this system reduces heat demand by up

to 25% while ensuring uniform drying of wood materials. This

energy-efficient system is highly adaptable and can be

configured to suit different types of wood, making it a valuable

addition to any woodworking or timber processing operation that

seeks to improve its sustainability practices.

Conclusion: Shaping the Future of Woodworking

The DREMA 2025 Gold Medal winners highlight a strong trend in

the woodworking industry towards automation, sustainability, and

innovation. These advanced technologies are setting new

benchmarks for the furniture and woodworking sectors, helping

manufacturers boost efficiency, precision, and environmental

responsibility. As the industry evolves, these winners exemplify

the future of woodworking: more efficient, automated, and

sustainable. With such cutting-edge solutions now available, the

woodworking sector is poised for a new era of growth and

innovation.

Source:

drema.pl