Unidbtplus operates an MDF plant at Gunsan. Photo Unidbtplus

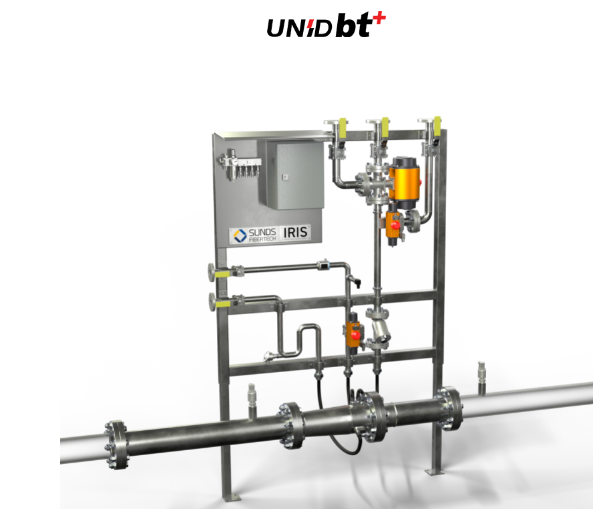

Sunds Fibertech has signed a contract with Unidbtplus to install

the Internal Resin Injection System at Unidbtplus’ plant in

South Korea. This innovative solution will boost energy

efficiency and sustainability in MDF production.

The Internal Resin Injection System, recognized for its high

return on investment and maintenance friendly operation, will

help Unidbtplus achieve significant resin and steam savings,

while also reducing CO2 emissions. This aligns with the

company’s ongoing commitment to sustainable and energy-efficient

manufacturing practices. Unidbtplus, a leading manufacturer of

wood-based materials, continues to solidify its position in the

South Korea MDF market with this innovative solution.

“We are proud that Unidbtplus has chosen Sunds Fibertech as its

partner for the resin system,” says Yves Michal, Head of Sales

at Sunds Fibertech. “We’ve always had a strong relationship with

Unidbtplus, and this project is truly exciting. As more

manufacturers recognize the advantages of the Internal Resin

Injection System over conventional systems, we look forward to

helping Unidbtplus unlock new levels of performance and

sustainability.”

By adopting cutting-edge resin injection technology, Unidbtplus

continues to lead the way in eco-friendly and cost-effective MDF

production, setting a benchmark for the industry in South Korea

and beyond.

Sunds Fibertech offers a wide range of process technologies for

panelboard production. Whether it’s about new machinery or

upgrades, we make sure your equipment is perfectly tailored for

your operation. Partner with us and enjoy new levels of

commercial and environmental benefits!

Source:

sundsfibertech.com